Which global regulatory bodies does Indivirtus support for GMP approvals?

We provide GMP readiness and audit preparation for EU-GMP, USFDA, WHO-GMP, PIC/S, TGA (Australia), Health Canada, ANVISA (Brazil), COFEPRIS (Mexico), and GCC nations.

What is included in a vendor assessment audit?

Our vendor audits assess compliance with GMP standards in terms of documentation, infrastructure, process capability, quality systems, and regulatory history.

How is the plant layout and process flow evaluated?

We assess the logical flow of materials and personnel, zoning, segregation, equipment placement, and overall facility design in line with GMP best practices.

Why is CAPA and risk management critical for GMP audits?

CAPA and risk management are central to regulatory compliance. We help design proactive systems to detect, correct, and prevent non-conformities.

What is a GAP assessment as per Schedule M?

It’s a comparison of your facility’s practices and documentation against India's Schedule M guidelines. We identify gaps and recommend remediation.

How soon can GMP readiness be achieved?

Readiness depends on the initial gap and facility type, but our approach typically enables preparation within 4–12 weeks.

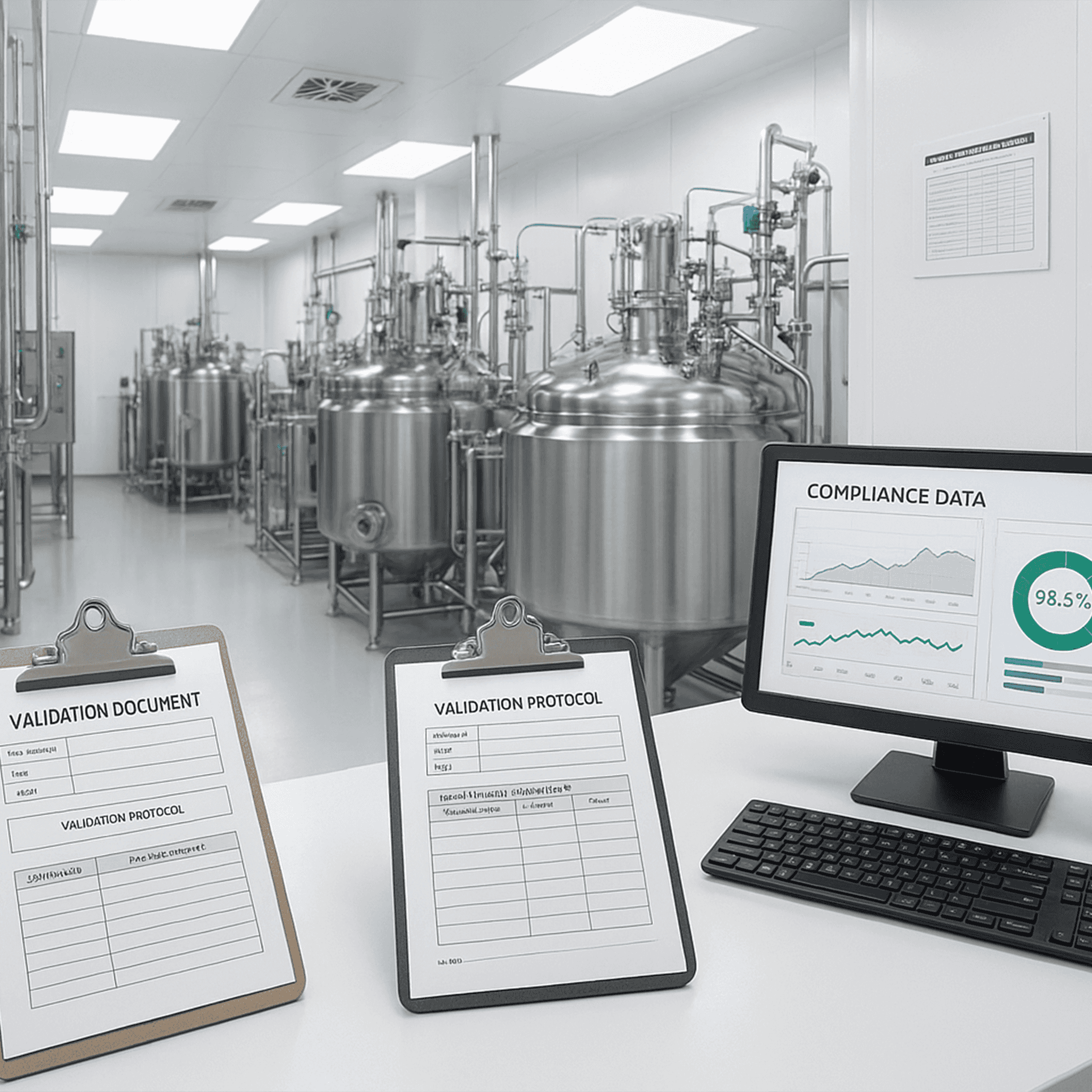

What is the purpose of GMP compliance audits?

GMP compliance audits ensure that pharmaceutical manufacturing processes, facilities, and documentation meet global regulatory standards like EU-GMP, USFDA, and WHO-GMP, ensuring product quality and patient safety.

How do you support regulatory inspections?

We provide on-site representation, mock inspections, audit response preparation, CAPA development, and follow-up support to address findings like FDA 483s or warning letters.

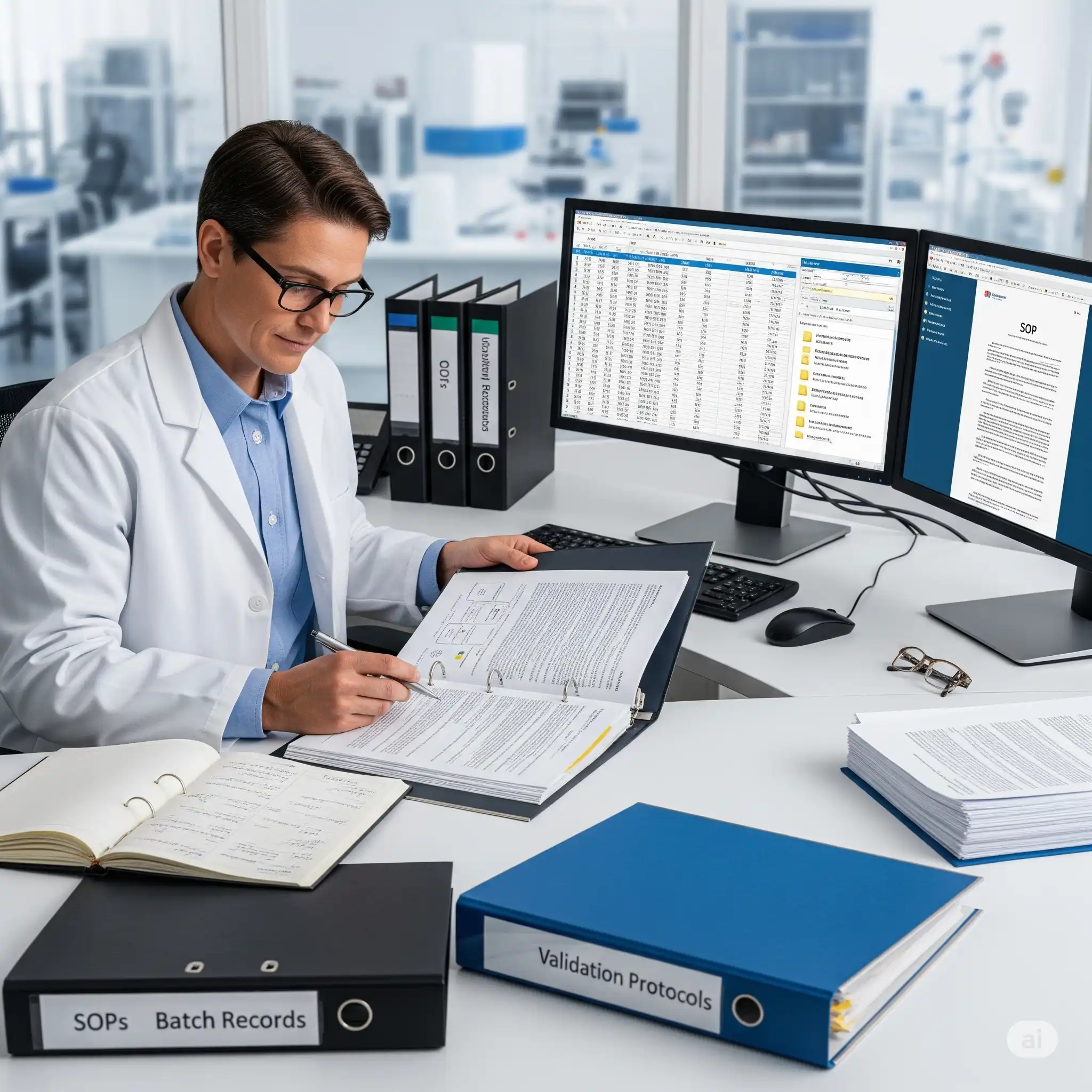

What is involved in regulatory dossier preparation?

We prepare and review CTD/eCTD modules, NDA, ANDA, IND, IMPD, and DMF submissions, including CMC documentation and GMP sections, to ensure compliance and readiness for regulatory review.

How long does a typical GMP audit or qualification process take?

The duration varies based on scope, but audits typically take 1–3 weeks, while facility qualifications (DQ/IQ/OQ/PQ) may take 2–8 weeks, depending on complexity.

Who benefits from your GMP approval services?

Pharmaceutical manufacturers, biotech firms, API producers, and contract manufacturers benefit by achieving regulatory compliance, streamlining approvals, and ensuring quality systems.

What is data integrity assessment, and why is it important?

Data integrity assessments verify that records and systems follow ALCOA+ principles, ensuring traceability and compliance with 21 CFR Part 11, which is critical for regulatory audits.